KWG0930-E Ultrasonic Metal Welding Ma... Metal ultrasonic welding machine are solution for...

PLN 0,00

|

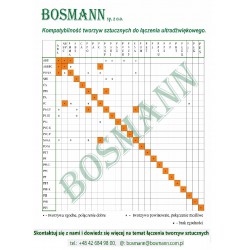

New Digital ultrasonic welding machines is equipped with automatic tuning frequency control for welding thermoplastics like PP, PC, PU, PA, PBT, PES, PVC, PM, etc. It is possible to adjust: welding time, rate of descent horn, pressure, pressure welding, welding depth.

|

|

Features:

1. Automatic frequency control. no need to adjust the horn's resonance.

2. Special circuit design, resonance frequency compensation when loaded to improve welding ability

3. Full bridge IGBT modules are used in the generator to improve durability.

4. PWM (Pulse Width Modulation) amplitude control. linear adjustment from 50% to 100%.

5. PWM controls vibration during start-up to prevent horn damage due to hight voltage starts.

6. 8 selective start-up settings for ultrasonic activation to match various horn design requirements.

7. Ultrasonic frequency fluctuation and high-voltage and overload prodtecion.

8. Automatic frequency control technology, helps to avoid and increase in horn temperature which could lead to frequency offsets, and affect the welding quality.

9. LCD displays the ultrasonic frequency and ercentage of amplitude, making set up easy and clear.

10. Control panel used push button settings and LACD display for welding parameters.

11. Two welding models: TIME CONTROL / PRESSURE TRIGGER.

12. Horn moves using precision linear guides to ensure stabilit of the welding head.

13. Lower Horn posistion adjustment is made by micrometer adjustment.

14. Two lowering speed adjustments control the Horn downward speed from fast to slow, improving the welding stability.

15. Start-up automatic frequency self-checking is standard.

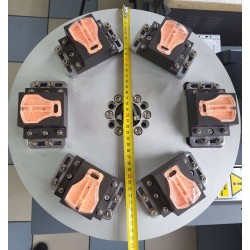

ULTRASONIC MACHINE KWD-2620 with ROTARY TABLE:

|

➥ Filtration industry |

|

|

➥ Ultrasonic welding of packaging made of synthetic materials, - ultrasonic technology guarantees sealing, tightness and protection of products. Welding of toys, home appliances and others. |

|

|

➥ Meets additional restrictions in terms of quality, durability of connections, safety and hygiene |

|

|

➥ Automotive industry, welding structural elements of cars and components, electronics industry, welding tapes for cables, welding covers, etc. |

|

|

➥ The KWD-2620 ultrasonic welding machine is used in production lines and works perfectly as an independent work station ➥ Ultrasonic machines are ecological solutions for joining synthetic materials ➥ Eco-friendly solution: Production based on ultrasonic welding takes place by eliminating additional binders such as: threads, glue, tapes. |

Ultrasonic control system:

1. LCD Display to show the weld time and piece counter

2. Push button Panel for setting Delay, Weld Duration, Hold time (0,01 ~9,99sec)

3. Selectable Welding Mode (Delay Time, Weld Duration, Hold Time)

4. Selectable Pre-triggering (Variable resistor. Trigger pressure setting)

6. Anti-tie down start switches. E stop for emergency cylinder up/ultrasonic vibration stop

Mechanical:

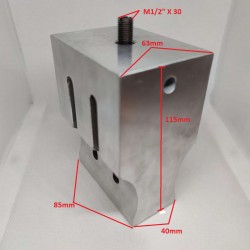

1. Standard Machines: 63Ø / Stroke 75mm cylinder (other cylinder specifications optional)

2. 100 Ø Machine Rigid column

3. Two steps (Fast, Slow) downward speed for Hone air cylinder

4. The Horn mechanism uses a Precision linear quide system

5. The lower position of the horn is set by micrometer adjustment without affecting other settings.

6. Air source: 6kg/cm

Technical parameters:

Power: 2600W,

Frequency: 20kHz

Power supply: 220V-240V, 50/60Hz, 15A

Cylinder: Ø63 x 75mm Dimensions: 370 x 670 x 1030 ~ 1330 (L x W x H)

Application: Machine for the thermoplastic parts assembly, Ploypropylene, polyester, polyethylene material and for the products market: Automotive, Furniture, Landscatping, Fitration, Medical, Cleaning and Textiles, Footwear industrial.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Skontaktuj się z nami i dowiedz się więcej

☎ BOSMANN sp. z o.o.

ul. J. Kilińskiego 210, 93-106 ŁÓDŹ, POLAND

☎ tel.: +(48) 42 684 98 00 kom.: +(48) 513 033 315 www.bosmann.com.pl @: bosmann@bosmann.com.pl

KSONIC KWD-2620 Ultrasonic plastic welding machine, ultrasonic plastic welder with digital generator (IGBT modules) for thermoplastic parts assembly. frequency: 20Khz, output: 2200W

Certificate: ISO9001, CE, UL

Delivery: in Stock

Produkty powiązane

Inne produkty w tej kategorii