KWG0930-E Ultrasonic Metal Welding Ma... Metal ultrasonic welding machine are solution for...

PLN 0,00

|

Ultrasonic welding machines is equipped with automatic tuning frequency control for welding thermoplastics like PP, PC, PU, PA, PBT, PES, PVC, PM, etc. It is possible to adjust: welding time, rate of descent horn, pressure, pressure welding, welding depth.

|

|

The feature of polyethylene welding

1. Imported accessories adopted

2. Four balance adopted

3. The machine head up and down automatically

4.Sheet metal nonrectangular columns,Coattails groove design,welding more precision.

5. Tow hands pneumatic,Have emergency braking in front,also can be added the external swith.

6. It can weld thermo plastic excluding Teflon

7. It has transient welding time with common range from 0.01 to 3second

8. It can weld surface via media such as water and oil.

9. It has a practical welding effect

10. It can be used in either direct or conductive weld

11. The weld energy varies with plastic materials ,The weld method is not to make whole material of welder part vibrate through ultrasonic,but only to make appropriate vibration surface vibrate and generate heat,there for ,there is no worry about any scar left on product surface,which is the charecteristic of conductive weld, while welding relatively hard plastic part,the weld effect is much better.

12. Ultrasonic weld will not give rise to any toxic substance as chemical,it is a kind of safe weld method.

13. Lower Horn posistion adjustment is made by micrometer adjustment.

14. Two lowering speed adjustments control the Horn downward speed from fast to slow, improving the welding stability.

15. Start-up automatic frequency self-checking is standard.

ULTRASONIC MACHINE

|

➥ Widely used in the automotive industry, electronic industry, medical industry, household appliances, woven apparel, office supplies, packaging industry, toy industry and so on. Such as plastic body parts, car doors, car dashboard, lights,mirrors, sun visor, interior parts, filters, reflective material, reflective spike,bumper, cable, motorcycle plastic filter, radiator , tanks, pallet plates. |

|

|

➥ Ultrasonic welding of Plastic electronics: prepaid water meters, communications equipment, atheism phone, mobile phone accessories, cell phone case, battery case, charger, maintenance valve regulated lead-acid batteries, 3-inch floppy disk, U disk, SD card, CF card, USB connectors, Bluetoot |

|

|

➥ watches, kitchen utensils, oral liquid bottle, drip caps, mobile phone accessories, gold soft brush, daily necessities, health supplies, children's products, air mattresses, clothes hangers, tool holder, coffee pot, cover and Civil speaker grille metal surface |

|

|

➥ Automotive industry, welding structural elements of cars and components, electronics industry, welding tapes for cables, welding covers, etc. |

|

|

➥ The ultrasonic welding machine is used in production lines and works perfectly as an independent work station ➥ Ultrasonic machines are ecological solutions for joining synthetic materials ➥ Eco-friendly solution: Production based on ultrasonic welding takes place by eliminating additional binders such as: threads, glue, tapes. |

Ultrasonic control system:

1. Push button Panel for setting Delay, Weld Duration, Hold time

2. Selectable Welding Mode (Delay Time, Weld Duration, Hold Time)

3. Selectable Pre-triggering (Variable resistor. Trigger pressure setting)

4. Anti-tie down start switches. E stop for emergency cylinder up/ultrasonic vibration stop

Mechanical:

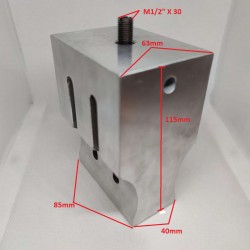

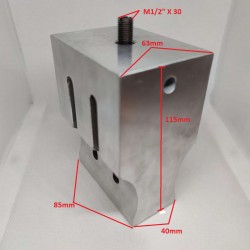

1. Standard Machines: 63Ø / Stroke 75mm cylinder (other cylinder specifications optional)

2. 100 Ø Machine Rigid column

3. Two steps (Fast, Slow) downward speed for Hone air cylinder

4. The Horn mechanism uses a Precision linear quide system

5. The lower position of the horn is set by micrometer adjustment without affecting other settings.

6. Air source: 6kg/cm

Technical parameters:

Frequency: 20kHz

Power: 2000W

Net Weight: 90kg

Press size:650mm*400mm*1400mm

Welding capability: ø200mm

Generator size: 511mm*401mm*141mm

Operating Mode: Time mode /Energy mode/vibration drop function

Application: Machine for the thermoplastic parts assembly, Ploypropylene, polyester, polyethylene material and for the products market: Automotive, Furniture, Landscatping, Fitration, Medical, Cleaning and Textiles, Footwear industrial.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Skontaktuj się z nami i dowiedz się więcej

☎ BOSMANN sp. z o.o.

ul. J. Kilińskiego 210, 93-106 ŁÓDŹ, POLAND

☎ tel.: +(48) 42 684 98 00 kom.: +(48) 513 033 315 www.bosmann.com.pl @: bosmann@bosmann.com.pl

LINGKE L3000 CE Ultrasonic plastic welding machine, ultrasonic plastic welder with digital generator for thermoplastic parts assembly.

frequency: 20Khz, output: 2000W Lingke

Produkty powiązane

Inne produkty w tej kategorii