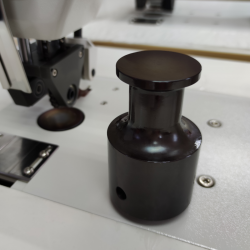

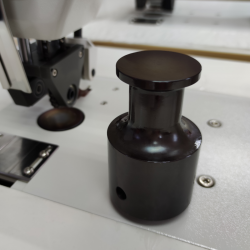

The roller acts as a matrix, focusing vibrations at a specific point in the material. Depending on the roller pattern, various effects are possible, such as decorative finishing, cutting edges, welding layers of material, or cutting holes of various shapes. Our rollers, made of the highest quality steel, guarantee not only durability but also excellent quality of the final connections and obtained patterns.

|

Technical parameters of the roller:

|

|

The use of rollers for decorative cutting of fabrics

Tablecloths, Lace, Decorative appliques, Ribbons, Decorative ribbons, Wire ribbons, Curtains, Trims,

Welding rollers: Joining synthetic materials, non-woven fabric, fleece, polypropylene, polyester, etc.

Emphasize the elegance of your tablecloths and napkins with our decorative cutting and welding roller for an ultrasonic machine.

Contact us at bosmann@bosmann.com.pl and check out our roller patterns or share your own designs and we will design rollers tailored to your production needs.

The cutting process takes place without smoke and without the risk of material ignition. Materials subjected to the ultrasonic welding process must contain at least 65% of plastics, with the best results for polypropylene, polyester, etc. Thanks to ultrasonic technology, the edges of the fabric do not shrink or wrinkle. Our roller is perfect for the decorative finishing of fabric edges. You can create elegant patterns, decorative details, lace, napkins, and tablecloths as well as other eye-catching finishes that will add a unique character to your textiles.

By sending an e-mail to bosmann@bosmann.com.pl, you can count on access to our rich collection of roller patterns. We offer a variety of motifs that are perfect for the production of decorative tablecloths. If you have your own ideas, share them with us! We will be happy to collaborate with you and can adapt our rollers to your unique projects if requested.

Take your decorative textile production to the next level with the best ultrasonic machine for napkins and tablecloths. We are proud to present a solution that works perfectly with our Ultrasonic Machine Rollers, designed specifically for the decorative finishing of fabric edges.

Take your decorative textile production to the next level with the best ultrasonic machine for napkins and tablecloths.

We are proud to present a solution that works perfectly with our Ultrasonic Machine rollers, designed specifically for decorative finishing of fabric edges.

.jpg) |

|

Contact us and find out more: BOSMANN sp. z o.o. tel.: +48 42 684 98 00, e-mail: bosmann@bosmann.com.pl

Produkty powiązane

Inne produkty w tej kategorii